Since 1999

? FAQ and Restoration Tips

!

![]()

This page will answer many of the most common questions that are not covered on the Help screens associated with the other web pages. Contact us by email if you have a question not listed.

| What is it Worth / Where can I sell it? |

| Where can I buy a used V-M? |

| I’m a new owner |

| I need parts! |

| Record Changer and Phono FAQs |

| Amplifier and Speaker FAQs |

| Tape Recorder FAQs |

| Case Care |

| Shipping |

Q1-1: I have a V-M product. What is it worth?

A1-1: Your Voice of Music®, V-M Professional® or V-M Educational Series® product was built in Benton Harbor, Michigan by hard working people who really cared about what they were doing. As for value, I would say its priceless! In terms of cash exchanging hands - well, that’s hard to determine because condition, presentation to the seller, the economy and other factors come in to play. I do not know prices. Go to the resale web sites like eBay or etsy and search on completed auctions for equipment with similar features to yours. Consoles show up more frequently on local websites like craigslist.org. Some of the audio forum websites also have classified ads. These resources will give you some idea of current value.

Q1-2: I have a V-M product. Where can I sell it?

A1-2: If the product you have is small enough to ship then a resale site such as eBay or etsy is a good avenue. It is a selling point that parts, service and owner’s manuals are available from V-M Audio Enthusiasts, so be sure to mention that in your listing.

If you have a console, then your best bet is to find someone local. Use your social network at work, church, etc to find a buyer. Local websites, classifieds by community like craigslist.org, and merchandise publications are other options. Where Can I Buy a Used V-M?

Q2-1: I am looking for a model like I used to have. Where can I find it?

A2-1: There are some resellers listed on our Links page with restored equipment. Other suggestions include auction sites like eBay.com, classified ad sites like craigslist.org, your Grandma’s basement, garage sales, flea markets, and thrift shops. Some communities have old radio/ham/antique audio clubs and many have swap meets or flea markets at their gatherings. Finally, there are still some schools that have not cleaned out some of their V-M “educational series” phonos and tape recorders so be on the alert for school auctions.

Q2-2: I am looking for the V-M demonstration (tape, record) that came with my old (recorder, phono). Where can I find it?

A2-2: The best answer here is eBay. These do show up for sale from time to time. I’m a New Owner

Q3-1: I am now the owner of a vintage audio product. Should I plug it in?

A3-1: This is a very difficult question to answer! I can only provide some considerations: If you and the previous owner do not know when the last time it was plugged in and operating, doing so now could seriously damage any vintage electronic product. The older the equipment is, the higher the risk. With older tube type equipment having large transformers, the risk involves shorted power supply capacitors which can cause the transformer to overheat and start smoking. Transformers are expensive to replace if they can be replaced at all. To avoid the risk, replace the electrolytic capacitors first or seek professional help before powering up. If you do plug an amplified product in and start to hear a loud hum, immediately shut it off. With all electrical products, inspect the power cord first to make sure it is in good shape.

Q3-2: I am now the owner of a vintage V-M product - what information is available to get it / keep it working properly?

A3-2: I recommend starting with the technical literature! Service manuals are available for all V-M products. They have important trouble shooting tips, illustrations, schematics, and lubrication information. From the service manual, you can determine what parts you may need and inquire with the correct V-M part number! Owner’s manuals are available for almost all V-M products. Manuals may be original or reprints depending on the model. Contact us by email with the V-M Model number of the unit you have and we will quote price of manuals with shipping and handling! Also read the Record Changer and Phono FAQs, Amplifier and Speaker FAQs, and Tape Recorder FAQs for important information on what maintenance your model is likely to need. I Need Parts!

Q4-1: I need an idler wheel - or needle, stylus, or cartridge - or other part. How should I proceed?

A4-1: Please click on Start Here! where this question is answered! We have an enormous variety of parts for V-M equipment and commonly needed items for non V-M products as well. Commonly needed items can now be ordered directly. Emails are answered promptly and we will advise for any items that are not orderable on-line. Please remember to put our email address on your “safe list” or you may not receive our reply. Check your “junk mail” first and call on the phone if you didn’t hear back in 36 hours (most emails returned within a few hours). Record Changer and Phono FAQs

Q5-1: What is the difference between a record changer, turntable, phonograph and record player?

A5-1: A record changer (sometimes also called an automatic turntable) can stack and play multiple records automatically. A manual turntable (or turntable) has capability to play one record at a time. A third classification is a “semi automatic turntable”, which may pick up the tone arm at the end of the record and shut itself off after the record has played. It may also have a similar capability to move the tone arm over and lower it to play a record once it has been manually placed on the platter. Unfortunately, the term “turntable” can also refer to just the platter that spins the records. All of these variations require an external amplifier and speakers to hear sound. A combination of a record changer, amplifier, and speaker all in one unit may be called a record player or phonograph.

Q5-2: What is the difference between a needle and a cartridge?

A5-2: The needle or stylus is the device that fits in the record groove and moves according to the impression of the music made in the vinyl. It typically consists of at least one tip (usually synthetic diamond or sapphire), a cantilever that the tip(s) is mounted to, and either a plastic or metal lever or needle body so that it can be attached to the cartridge. Please see examples of various types of needles on the Needles/Stylli page. In general, the needle is a separate, serviceable item and if all you need is the needle, best to only buy that. Please see the Needle Help! page for more information on needle tips, life expectancy, and replacement identification.

The cartridge is what the needle is connected to, and its job is to take the vibrations resulting from the travel of the needle tip in the groove and translate them into electrical signals that can then be amplified and reproduced as sound through a speaker. Most cartridges are either of the crystal, ceramic or magnetic types. The ability to substitute one type for another is limited. Please see examples of various types of cartridges on the

Cartridges page (there you will see cartridges with needles installed as this is how they are sold). Please see other FAQ’s below about how to tell if you need a new cartridge, along with information provided on the

Cartridge Help! page.

Q5-3: What are the keys to maintaining good vintage record changer operation?

A5-3: They are:

1. Lubrication

2. Idler wheel

3. Cartridge and Needle

First – Lubrication

This is the most important key! How would your car run if you didn’t change the oil in 40 years? As lubrication ages, it can become sticky like glue or even dry up into a powdery substance. Old lubrication can cause a variety of ailments including erratic operation, slow record change cycling, failing to drop records properly, not shutting off after the last record plays or shutting off before the last record plays to name a few. The solution is to completely tear down the changer, degrease all the affected parts, and reassemble and relubricate. This should be attempted only with the service manuals and by someone who is mechanically inclined as there are many small parts. In addition, the motor should likewise be carefully disassembled and cleaned and lubricated. Especially if the turntable platter is running “slow”.

Second – Idler wheel

The idler wheel should be inspected and replaced as necessary. The idler wheel’s rubber should not be hard, cracked, or appear “shiny” at the driving surface. On V-M changers, this is a relatively simple task. The turntable retaining clip or “o-ring” is removed and the turntable removed from the spindle. The idler wheel is now in view. The small clip should be removed and there should be a small fibre washer on the top of the wheel and the bottom. Do not loose these parts but they are available if you do. Clean up the shaft with rubbing alcohol and put one very small drop of light weight oil on the shaft before installing the replacement idler wheel.

Third – Cartridge and Needle

Your keys to good sound. The needle or stylus, should be replaced if there is any doubt about how old it is and how much “mileage” it has on it. Worn needles ruin records! Note that some of the older cartridges have two needles usually held in with tiny screws. On tip for playing LP, 45 and 16 rpm records and one for 78 rpm records.

Before replacing any of these, it is advisable to check the health of the cartridge. If it needs to be replaced, the needle(s) the replacement requires may be different than the original. A cartridge is defective if the sound plays in only one channel, cuts in and out as the record plays in one or both channels, or produces no sound whatsoever. On this latter condition (no sound), it is important to make sure the amplifier is working properly as that could also be a culprit. See the

Amplifier and Speaker FAQ’s for more on amplifier health.

Do take the time to determine your cartridge status! If the cartridge is an older ceramic or crystal obsolete type but is still functional, replacing it with a new old stock cartridge of the same type may be expensive (if even possible) and unnecessary. A new needle is quick and easy to install and may be all that is required.

Q5-4: My record changer runs slow - what could be the problem?

A5-4: Phonograph and tape recorder motors need lubrication just like any other mechanical component that moves - especially if the motor and unit have been stored in a damp basement or garage for a period of time. Assuming the motor does not need replacing for other reasons, here is how to bring the motor in your machine roaring back to life:

1. First, take the motor apart. Carefully remove the lower bearings from the shaft. Remove the upper bearing and rotor assy. Pay attention to which way the stator is oriented (mark "up" with a grease pencil).

2. Clean the bearings to the extent you can with rubbing alcohol. On most motors it is not advisable to remove the upper bearing from the shaft as that would involve removing a pressed on stepped shaft.

3. Relubricate the bearings with a good quality non-detergent light weight machine oil. Sewing machine oil or similar SAE 20 oil will work. Make sure the bearings can pivot in the bearing housings.

4. Reassemble the motor making sure the correct standoff spacers are used to keep the top plate level with the stator. The bearings are self aligning - so gently tap the end of shaft while the motor is running to ensure the bearings do not bind. If the motor runs backwards, reassemble with the stator oriented in the opposite direction.

5. If the above process fails to resolve the problem, a replacement motor may be necessary. For V-M products, click on

Other V-M Phono Parts and

Phono Motor Identification for more information.

Q5-5: I don’t hear any sound coming out of my phonograph, except for a faint sound when I put my ear next to the tone arm. What’s wrong?

A5-5: If there is no or very low sound coming out of the unit, the phonograph pickup cartridge may be “dead”. Here is a simple check – note: wear shoes and stand on carpeted surface when conducting this test: If you can make contact with your finger on the wires leading to the cartridge and hear a loud buzz with the unit on and volume up, then the amplifier is probably fine and the cartridge is the culprit. If you do not hear a loud buzz, then you need to have your phonograph checked by a professional servicer.

Q5-6: How do I know if I need a needle or a cartridge?

A5-6: If your tone arm skates across the record, you most likely need a new needle.

However, before ordering, check to see if the cartridge is good as follows. With

your record player and amplifier on, and volume turned up at least a 1/4 of the way,

perform the following "scratch test". Rub your finger over the needle (or if missing,

across the rubber bridge or cradle that the needle shank rests on). If you hear a clean

scratching sound coming out of your speaker(s), then the cartridge is likely to be

still good. If the sound coming out is breaking up, or you hear a "pop" sound,

then the cartridge may be cutting in and out which means it had better be replaced.

If the needle is missing, also inspect the cartridge physically for damage to any

retaining straps that are meant to hold the needle in place. If it appears that

there is no way to retain the needle, the cartridge must be replaced.

Q5-7: I just replaced the needle and still some of my records skip! What's wrong?

A5-7: There may not be anything wrong - assuming your vintage equipment is

in good operating condition. The issue may be a matter of incompatibility.

Older record players and phonographs in the popular price field may have cartridges that

won't track newer records. For this type of equipment the "Rule of 10" is good

to keep in mind: Records that are 10 years newer than the equipment they are

being played on may skip. Of course a better cartridge may add years to

this and allow more records to be played without skipping, but there comes a point

where the rest of the technology in the design of the record player is just not up

to the task. These record players should be enjoyed for what they are - and if you

plan on playing a lot of newer records, the purchase of more modern equipment is advised.

Q5-8: I would like to make certain modifications to my phonograph to play stereo records / get better sound / etc. What parts do I need?

A5-8: This is too difficult a question to answer in general! Besides

potentially degrading the collector value of an “all

original” machine, it is very difficult to anticipate all

requirements and parts that would make the modification

successful. An exception can sometimes be made if a better

tracking and more reliable cartridge is available that can

be installed with minimal modification to the record player.

Cartridge substitution is increasingly a reality in the 21st

Century as new old stock exact replacement cartridges sell

out. Click on

Cartridge Substitution Help! for more information on

what this entails.

Q5-9: Can I purchase a replacement record changer to install in my phono?

A5-9: Replacement changers were sold years ago in several varieties but they no longer make sense. A new old stock replacement changer even if you can find one, might not be compatible and would require the same time and effort to restore as a used changer because it’s old! Replacement changers were usually installed by servicers who took into account the correct AC power hookup, cartridge compatibility, and the mounting board pattern when selecting a replacement changer. If you have a V-M changer in your phono, the best bet is to restore it or have us restore it. If the changer was made by someone else and it needs parts other than an idler wheel, center post, or needle and cartridge which we carry, then finding another similar changer for parts is an option.

Q6-1: What are the keys to maintaining good vintage amplifier operation?

A6-1: There is really only one key! Healthy capacitors – especially the electrolytic capacitors in the power supply! If these parts fail, they can short out the transformer (on units so equipped) and burn it up. The transformer may not be replaceable and is very expensive if a replacement can be found. Capacitors are like bread – they become stale if they sit around. So replacements should always be of recent manufacture as these parts have a shelf life.

Purchasing capacitors may at first appear to be a problem as the values made today are not the same ones as 30+ years ago. Fortunately, it is not a problem as long as the following three rules are observed:

1. Capacitance values should be close. For example, a 33uf will work where the original is a 30uf.

2. Voltage should be the same or greater. For example, a capacitor rated at 250 volts can be safely replaced with a capacitor rated at 350 volts, but not one rated at 125 volts.

3. Make SURE that you are buying the right type of capacitor. There are electrolytic and non-electrolytic types used in most amplifiers. Electrolytic capacitors are polarized and must be connected with the correct polarity as shown on the schematic.

Another difference between yesterday and today is that multi-section capacitors are no longer in high volume production. Your amplifier may have an aluminum “can” or brown wax covered tubular capacitor that is really 2 or more capacitors in one. If the exact replacement is not available or affordable, these components can be effectively replaced by replacing each element with an individual capacitor. Often, the original is left in place (for authenticity) and the individual replacements wired in underneath. If the original is left in place, it is only there for looks – it must be unhooked electrically from the circuit and the new ones wired in its place. Shrink tubing is a good idea to prevent the leads on the capacitors from touching something they shouldn't.

The normal priority order for replacing capacitors is 1) power supply and any other electrolytics. 2) older style non-electrolytics with wax coating. 3) others – usually the newer sealed capacitors are OK. With healthy capacitors, the status of other components can be more readily assessed. Tubes and transistors are often thought to be the culprits of poor sound – and these components can fail – but often it is bad capacitors that are really responsible.

Q6-2: I think I need new tubes. Can you help?

A6-2: We try and talk people out of buying new tubes unless they are sure they are needed! New old stock tubes are getting expensive and in our experience, may not be needed. Tubes being manufactured today in Russia or China are a lower cost alternative. The quality of these tubes varies. As it says in A6-1, the most important consideration is to get the amplifier rebuilt with new capacitors and other parts as needed. Then the health of the tubes should be assessed. Output tubes and rectifier tubes are worked the hardest and may need replacing. In our experience, the others are usually OK and we don’t replace them in our own work if not needed. For tubes that do need replacing, we are happy to quote price with shipping and handling.

Q6-3: The volume or tone controls cut in and out or produce “static” when I move them. How do I fix it?

A6-3: Your volume or tone control probably just needs a good cleaning. If you are mechanically inclined, you can remove the back of the console or access the amplifier and carefully disassemble it until you can gain access to the controls. Places like Radio Shack sell "control cleaner" or "tuner lube" that is in a spray can with a thin red snout for spraying it in tight places. You need to gain access to the control and stick the snout into the slot where the wires are soldered and spray a brief while - and move the control back and forth. One or two applications should take care of the problem. If that does not do the trick, and if your unit is a tube unit, it is possible a tube is making poor contact with the tube socket. Remove each tube and use a pencil eraser or other mild abrasive to clean the tube contacts. Reassemble and check to see that the problem has gone away.

Q6-4: My speaker has a rattle/tear/poor sound. Can I get a new one?

A6-4: Certainly, Contact us by email with the V-M model number of your model. The part number of the speaker is in the service manual or may be printed on the speaker itself (look for 4 or 5 digit number). We may advise that this part is not available. If so, yours can be rebuilt. We use The Circuit Shop, link on our Links page.

Q6-5: I need new grill cloth for my speakers. Where can I find it?

A6-5: It used to be that reproduction grill cloth was only available for old radios. Lately, “hi fi” era cloths have become available for vintage guitar amplifiers. One source is Antique Radio Supply, link on our Links page. Best to use your favorite search engine to see what else is out there.

Q6-6: My amplifier’s transformer (power or output) has failed. Can I get a new one?

A6-6: Certainly, Contact us by email with the V-M model number of your model. The part number of the transformer is in the service manual or may be stamped on the top or side of the transformer itself (look for 5 digit number). We may advise that this part is not available. If so, try Hammond Manufacturing, link on our Links page.

Q6-7: My V-M phonograph, console, amplifier has “tone-o-matic®” and “acoustic contour®” controls. What do these do?

A6-7: Our ears do not hear all frequencies the same at all volume levels. The “tone-o- matic®” control boosts highs and lows at low sound levels. Beyond the mid point of its rotation, this control operates as a volume control only. More modern equipment with a “loudness” control also has this same functionality built in.

The “acoustic contour®” control has settings of S (small), M (medium), and L (large) room sizes. According to the sales literature, it shapes the music to fit the room, to solve the problem of decreasing fidelity at increased volumes. The Owner’s manual explains how to use the control. Tape Recorder FAQs

Q7-1: I have this V-M tape recorder, but when I turn it on and push PLAY, nothing happens?

A7-1: If the tape recorder has not been used in a long time, read Q3-1 before proceeding. Your V-M tape-o-matic® tape recorder may contain an automatic shutoff mechanism that is activated when you push PLAY if no tape is threaded past it. First, make sure that the STOP button is fully depressed in its LOCKED position. Then, turn on the power and the pilot light (if present) should light and you should hear the motor run. The instructions for threading a tape are included in the lid of most models - if the unit has power but the reels fail to move in other modes (PLAY, RECORD, FAST FORWARD, REWIND), then a faulty belt or wheel is most likely the cause. Click on Contact us by email for more information – V-M tape recorder parts are in good supply!

Q7-2: What should I do to maintain my V-M tape recorder?

A7-2: A tape recorder has both mechanical and electrical needs. For the electrical needs, especially if you hear a loud hum when recorder is on, please see the first item in the Amplifier and Speaker FAQs. For mechanical, it boils down to clean heads, good lubrication, and good rubber parts. Tape recorder heads, guides, and rollers should be cleaned with cotton swabs and isopropyl rubbing alcohol, at least 90% pure. Tape recorder heads may need to be demagnetized if used often. Contact us by email for a quote on the VM 32026 Tape Recorder Maintenance manual. Good lubrication involves taking the recorder apart, removing all the old, sticky lubrication and replacing it with fresh lubrication per service manual instructions. Rubber parts (wheels, motor mounts, belts) should be inspected and replaced as necessary. Click on V-M Tape Recorder Repair Kits to order the most needed parts and manuals, or Contact us by email for a quote on all needed V-M parts and manuals.

Q7-3: I have this tape recorder that needs work but what I really want to do is digitize some old tapes.

A7-3: Here you have a decision to make. Spending money on fixing up a tape recorder for a one time use – versus paying for an audio transfer service. Our interest here is clearly in helping tape recorder owners refurbish their machines to be used for their intended purpose – as high fidelity tape recording and playback instruments. Fixing up a tape recorder with the intent of selling it when done may not be worth the investment. Additionally, the old tapes may be in bad shape and this you will not know until you have invested in fixing your old recorder. For transfer services, use your favorite search engine to find current businesses

Q7-4: When I play my old tapes, they slow down. What’s wrong?

A7-4: First make sure all the tape transport parts that are in the tape path are clean. Use isopropyl rubbing alcohol, highest purity you can find and cotton swabs to clean the tape guides, tape heads, capstan and pressure roller. If the condition persists, its probably the old tapes! The binder that holds the oxide formulation to the plastic tape breaks down with time and this increases friction and drag as the tape goes through the tape recorder, slowing the machine down. If you search for “old magnetic tape” or “magnetic tape deterioration” on line, you’ll find more information, including a “baking” process that is supposed to reset the binder and make the tapes usable again. We have not experimented with this process and cannot advise further.

Q7-5: I have a switch on my V-M tape recorder with two positions called “Stacked” and “Staggered”. What does it do?

A7-5: First, a little history. The very first stereo format was on reel to reel tape! V-M Corporation offered a conversion kit for the venerable Model 700 in 1955 - some three years before stereo records and five years before stereo FM broadcasts! The first format? Very simple - take a second half track monaural head, turn it upside down, and mount it to the right of the existing monaural head. Connect it up with another pre-amp and you have the “staggered” stereo tape format! The tapes were recorded with the starting points of the “L” and “R” tracks “staggered” so that both signals would be in sync when picked up by the playback heads. This format is also called “offset”. In 1958, as magnetic head manufacturing capabilities improved, the “stacked” or “in-line” format was invented - and remained the broadcast standard for many years - the so-called “half track stereo” format. The V-M Model 714 was a hit because it had a switch to play both the newer “stacked” and older “staggered” formats. In November of 1959, V-M brought out the Model 720, one of the first on the market to play the new “quarter track” stereo tapes.

Q7-6: I have “Add+A+Track®” on my V-M tape recorder. What is it?

A7-6: This feature allows you to play one track while recording on another. For example, you can play an instrumental piece recorded on one channel, and listen to it while you sing the words and record them on the other channel. When the tape is played back, you will hear both. An early form of “sound on sound”. A more involved explanation is included in the Owner’s manual, available from us!

Case Care

Q8-1: The fabric on the case of my V-M product is dirty and dull. What should I do to clean it?

A8-1: To clean the leatherette, we recommend waterless automotive hand cleaner. Gentle enough for hands but tough on dirt. Actually helps "feed" the leatherette and prevents it getting brittle. Rub it in and wipe clean with a soft dry cloth. A fine bristle (not stiff) toothbrush can be used to "get in the grain". Repeat procedure if case is heavily soiled. Of course, always test on a small surface first to make sure the leatherette is color fast! Get the plain hand cleaner – not one that contains pumice or other abrasives. Loose and frayed fabric can be glued down by applying wood glue on a toothpick to the underside of the fabric for a much neater appearance. The leatherette should be allowed to dry for two or three weeks after which a polish may be applied. Shipping

Q9-1: I am going to ship this unit - what do I do to ensure safe arrival?

A9-1: The BEST insurance that your prized V-M will get there in one piece is GREAT and AMPLE PACKAGING!!!

• Unit should be double-boxed. Inner box about the size of the unit, and the outer box being big enough to allow for at least 5 inches of packaging on ALL sides - that means, outer box is 10 inches longer, 10 inches wider, and 10 inches taller than the inner box.

• Use bubble wrap, especially for electronic items as it is the best for absorbing energy and protecting your model during shipping.

If

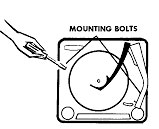

your model contains a record changer

• To unfloat changer (1200, 1500 series and up): Locate two mounting bolts clearly visible from topside. One is under the tone arm and the other on the opposite side of the platter. Turn bolts COUNTER-CLOCKWISE until changer rests securely on its base! Do this to prevent damage to changer and case during shipment.

If your model contains a tape recorder

• Be sure the STOP button is fully depressed in its LOCKED position. Damage to the main escutcheon and/or a flat spot on the driving wheels can result if the STOP button is not fully depressed.

![]()

|

V-M Audio Enthusiasts -37530 E. Meadowhill Dr. - Northville, MI

48167

|